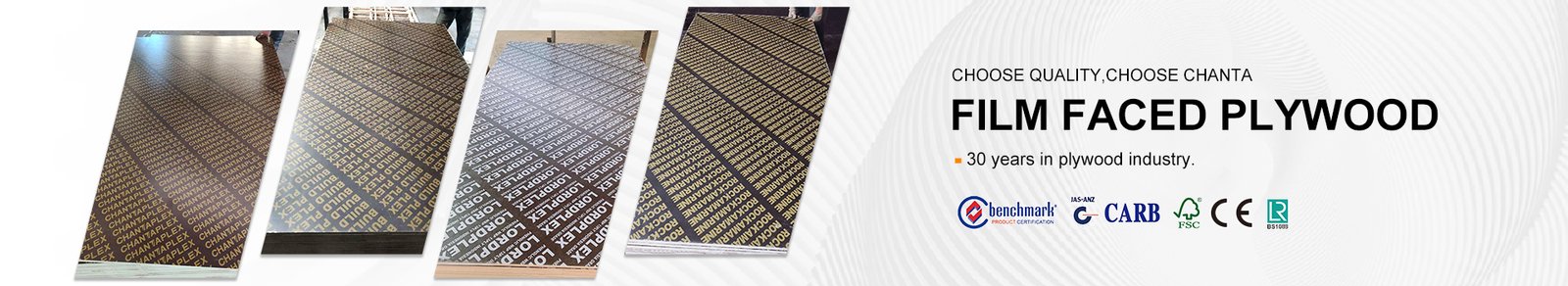

Vietnam Film Faced Plywood

Dimensions: 1220×2440 mm, 1250×3000 mm, or customized sizes

Thickness: 2.7–30 mm (commonly 4 mm, 6 mm, 9 mm, 12 mm, 18 mm)

Core: Birch, Eucalyptus, Poplar, Combi, or as requested

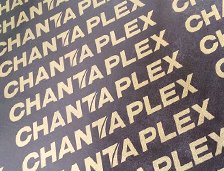

Face/Back: Black, Brown, Red, or Theil film, with optional logo printing

Glue: Phenolic or WBP adhesive

Reuse: 4–6, 8–12, 15–20, or 20–25 times, depending on correct handling

Certifications: FSC, CE, EUTR, CARB, EPA

Usage: Construction formwork, shuttering systems, and other related applications

Advantages:

1.Waterproof and capable of withstanding boiling without glue failure.

2.Smooth surface with high wear resistance.

3.Reusable up to 30 times with proper use.

Quality Options

Poplar Core

- Glue: WBP Melamine

- Size: 1220×2440 mm / 1250×2500 mm

- Thickness: 12 / 15 / 18 / 21 mm

- Reuse: 8–10 times

Eucalyptus Core

- Glue: WBP Phenolic

- Size: 1220×2440 mm / 1250×2500 mm

- Thickness: 17 / 18 / 21 mm

- Reuse: 15–18 times

Birch Core

- Glue: WBP Phenolic

- Size: 1220×2440 mm, 1250×2500 mm

- Thickness: 18 / 21 mm

- Reuse: 20–30 times

Film Types

Brown Film

Black Film

Green Film

Red Film

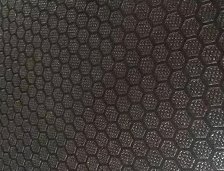

Anti-Slip Film

Logo Film

Our Factory

At TOP WOOD, the Vietnam manufacturing base of CHANTA Group, we take pride in being a trusted supplier of premium film faced plywood tailored for the European market. Backed by CHANTA’s decades of expertise in the global wood industry, we combine advanced production technology with strict European standards to deliver products of exceptional quality and consistency.

Our facility is equipped with state-of-the-art machinery and designed for large-scale, efficient production while maintaining meticulous quality control at every stage. Every sheet we produce fully complies with FSC certification processes, ensuring traceability, responsible sourcing, and a sustainable supply chain.

Film Faced Plywood Products

FAQ

What is film faced plywood?

Film faced plywood is a strong engineered panel with a phenolic film overlay. It is durable, water-resistant, and commonly used in concrete formwork and heavy-duty construction.

What sizes and thicknesses are available?

Standard sizes include 1220×2440mm (4×8 ft) and 1250×2500mm, with thickness options such as 12mm, 15mm, and 18mm. Custom sizes are also available for specific project requirements.

What are the main benefits?

Film faced plywood provides a smooth concrete finish, excellent load-bearing capacity, high water resistance, and reusability, reducing overall construction costs.

How many times can it be reused?

Typically, it can be reused 10–20 times depending on grade and handling. Premium quality panels can last longer with proper care and storage.

What are the typical applications?

It is widely used in concrete formwork, bridges, tunnels, truck and trailer flooring, packaging crates, and storage platforms.

Is it waterproof?

Yes. The phenolic film and adhesive provide high water resistance, but cut edges should be sealed to prevent moisture penetration.