Table of contents

Modern furniture emphasizes clean lines, efficiency, and durability. Behind the minimalist appearance lies a strong demand for materials that perform consistently under industrial production. Among many panel options, birch plywood has become a preferred choice for modern furniture manufacturers worldwide.

Its popularity comes from how well it balances structural performance, visual neutrality, and manufacturing efficiency. Rather than following trends, furniture makers choose birch plywood because it fits how modern furniture is designed, produced, and used.

Material Performance That Matches Modern Design

Modern furniture often features slim profiles, floating elements, and modular construction. These designs reduce visual weight but increase structural demands on materials.

Birch plywood offers high strength relative to its thickness. The dense birch veneers create panels that resist bending and sagging, even under long-term load. Shelves stay straight, cabinet bodies remain rigid, and table components maintain their form without excessive material thickness.

This strength allows designers to achieve lighter-looking furniture while maintaining real-world durability, a key requirement in both residential and commercial interiors.

Consistency That Supports Industrial Furniture Production

Modern furniture manufacturing depends on repeatability. CNC machines, automated drilling, and standardized assembly processes require materials that behave the same way every time.

Birch plywood provides consistent thickness, density, and bonding quality across panels. This predictability reduces machine recalibration, lowers defect rates, and improves overall production efficiency. For factories producing thousands of units, material consistency often matters more than small differences in raw material cost.

Other panel materials may vary more from batch to batch, which introduces unnecessary production risk.

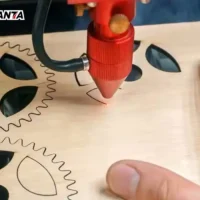

CNC Machining and Clean Edge Quality

CNC cutting defines modern furniture design. Panels must cut cleanly, hold tight tolerances, and maintain edge quality across complex shapes.

Birch plywood performs exceptionally well in CNC applications due to its uniform veneer layers and balanced density. Cuts remain smooth, edges resist splintering, and dimensional accuracy stays consistent throughout production runs.

Many modern furniture designs intentionally leave plywood edges exposed. Birch plywood supports this approach with a clean, structured layered appearance that aligns well with minimalist and Scandinavian-inspired aesthetics.

Surface Quality and Finishing Flexibility

Modern furniture often relies on neutral surfaces that adapt to different finishes and environments. Birch plywood provides a smooth, even surface that works well with a wide range of treatments.

Manufacturers commonly use birch plywood with:

- painted finishes

- laminates and melamine coatings

- thin decorative veneers

- clear or matte protective finishes

This flexibility allows factories to standardize materials while offering diverse product styles, simplifying inventory and production planning.

Cost Efficiency Across the Product Lifecycle

Birch plywood costs more than particle board or basic softwood plywood at the material level. However, modern furniture manufacturers evaluate cost across the entire product lifecycle rather than unit price alone.

| Factor | Birch Plywood | Lower-Cost Panels |

|---|---|---|

| Structural Strength | High | Low to medium |

| Production Stability | Consistent | Variable |

| Screw Holding | Strong | Limited |

| Defect Rate | Lower | Higher |

| Product Lifespan | Longer | Shorter |

When returns, repairs, and warranty claims are considered, birch plywood often delivers better long-term value.

Supply Stability and Global Manufacturing Trends

Modern furniture manufacturing requires stable, predictable supply chains. Birch plywood sourcing has diversified globally, allowing manufacturers to reduce dependence on a single region.

Suppliers with export-focused production, consistent specifications, and reliable logistics support continuous manufacturing without disruption. This supply stability has become a decisive factor in material selection for large furniture brands and OEM factories.

Final Thoughts

Birch plywood is popular in modern furniture because it aligns with both design philosophy and manufacturing reality. It delivers strength without bulk, consistency without complexity, and flexibility without sacrificing durability.

For furniture manufacturers focused on clean aesthetics, efficient production, and long-term reliability, birch plywood remains one of the most practical and trusted materials available today.